Search This Supplers Products:square steel piperectangular steel pipeERW steel pipehot galvanized steel pipelsaw steel pipeseamless steel pipe

- Home

- About us

- Products

- square&rectangular steel tube

- ERW steel pipe

- Ship Building Steel Pipe

- LSAW steel pipe

- seamless steel pipe

- galvanized steel pipe

- spiral steel pipe

- special shaped steel pipe

- line pipe&OCTG pipe

- stainless steel tube/coil

- Steel coil / steel strip / steel plate / angle steel / channel steel / H-section steel/steel spiral ground pile

- 分割线

- Wholesale Black Steel Pipe

- Wholesale Hot-dip Galvanized Steel Pipe

- Wholesale Pre-galvanized Steel Pipe

- Wholesale Cold-rolled steel pipe

- Wholesale LSAW Steel Pipe

- Wholesale Spiral Welded Pipe

- Wholesale Seamless Steel Pipe

- Wholesale Steel Coils/Sheets/Plates

- Wholesale Profile Steel

- Wholesale Stainless Steel Pipe

- Wholesale Pipe Fittings

- Faqs

- News

- Certificate

- Contact us

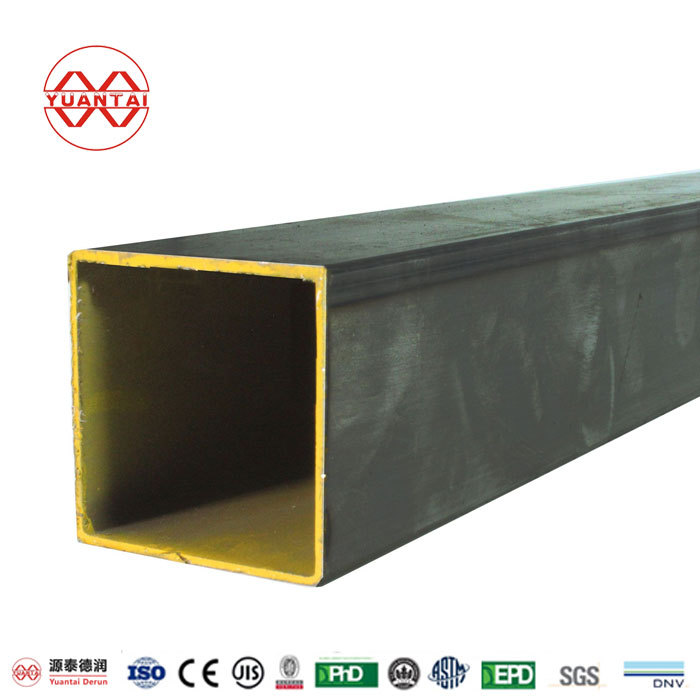

sharp corner square pipe|carbon steel|Structural use|Factory mass production customization|accept OEM ODM

- group name

- Black Square & Rectangular Steel Tube

- Min Order

- 2 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- ytdr-0099

- Nearest port for product export

- Tianjin, Dalian, Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, FCA, CPT

- Acceptable payment methods

- T/T, L/C, PayPal, Cash

- update time

- Sat, 14 Feb 2026 13:32:49 GMT

Paramtents

Outer diameter 10*10-1000*1000mm 10*15-800*1200mm

Thickness 0.5-60mm

Length 0.5-24M

Tolerance +-5%

Brand yuantai

Port Tianjin Xingang

MOQ 2-5 Tons

Payment method TT/LC

Packging & Delivery

-

Min Order2 ton

Briefing

Sharp angle square tube is a special square tube with sharp angle, which is usually used to cut or polish metal materials.

Detailed

sharp corner square pipe|carbon steel|Structural use|Factory mass production customization|accept OEM ODM

1、 Definition of rectangular tube with right angle/sharp angle

Sharp angle square tube is a special square tube with sharp angle, which is usually used to cut or polish metal materials. They are usually divided into large diameter and small diameter. Large caliber sharp corner square pipe: usually has a larger caliber, which can accommodate more materials and is very useful for grinding large objects. Small caliber sharp edge square tube: usually has a smaller caliber, which can accommodate less materials, and is very useful for polishing small objects.

The R angle of right angle/sharp angle square tube is different from that of ordinary circular arc square tube,

Right angle square tube: it is a right angle square tube whose R angle is not more than one time of the wall thickness.

Sharp angle square tube: when the wall thickness is not more than 3mm, the R angle is not more than 1mm; When the wall thickness is 3-8mm

R angle is not greater than 2mm; When the wall thickness is more than 8mm, R is not more than 3mm

It is a sharp square tube.

2、 R&D purpose of square and rectangular tubes with right/sharp corners

Mechanical guide rail, agricultural machinery framework, square pipe for steel and wood furniture and rectangular pipe for curtain wall construction

For the need of tolerance and fit, square and rectangular tubes with high dimensions are required, and high-precision square and rectangular tubes are required, among which these customers are the most

The focus is on the flatness of square and rectangular tubes. At present, square and rectangular tubes are mainly produced by cold drawing and continuous bending of steel plates

The flatness of finished steel pipe cannot meet the requirements of customers.

3、 Forming Technology of Square and Rectangular Tubes with Right/Sharp Angles

The square and rectangular tubes are processed and manufactured by the progressive roll extruding technology to improve the processing accuracy of the work roll and continuously adjust the roll

It is the assembly spacing, so that the plane size of the finished steel pipe can be accurately controlled.

1. Square and rectangular tubes are processed and manufactured by progressive roll extrusion technology, and square and rectangular tubes of different materials and specifications are collected

Tube plane rebound, variance analysis, experimental design, draw square tube plane rebound curve.

(Note: ① The right angled square and rectangular pipe can be welded with hot rolled strip steel as raw material, formed by cold bending, or formed into round pipe

Squaring, after heat treatment; ② Seamless square and rectangular tube, made of hot-rolled seamless tube

Type or cold bending)

2. According to the theory and practice of roll flattening, design and manufacture products that meet the strength requirements of different materials

Rollers requiring different final crown are used for production.

3. Strictly control the working roll processing accuracy and improve the flatness control accuracy of finished square and rectangular tubes.

4. The assembly spacing of the roll system shall be adjusted continuously to ensure the parallelism of the product with respect to the two planes.

4、 Specification of square and rectangular pipe with right angle/sharp angle

The size range of square tube with right angle/sharp angle is:

The side length is 30mmx30mm~400mmx400mm, and the wall thickness is 1mm~16mm;

The size range of right angle/sharp angle rectangular pipe is: side length 30mmx50mm~300mm x 600mm, wall thickness 1mm~16mm.

5、 Right angle/sharp angle square and rectangular pipe material

Domestic standards (GB/T700-2006, GB/T69-2015, GB/T/1591-2018):

Q195、Q235B、Q355(B/C/D)、Q420(B/C/D/E)、Q460(B/C/D/E)、20#、

45 #, etc.

European standard (EN10025-1993):

S235JR、S235J0、S355J2H、S355JRH、S355J0H、S460NL、S460ML。

American standard (ASTM A106/A500):

Gr.A、Gr.B、Gr.C、Gr.D、Gr50、Gr60、Gr65。

Japanese standard (JIS G3466):

SS330, SS400, STK490, etc.

6、 Executive standard for square and rectangular pipe with right angle/sharp angle

GB: GB/T6728-2017, GB/T3094-2012

European standards: DIN EN 10210, DIN EN 10219

American standard: ASTM A500

Japanese standard: JISG 3466

Australian Standard: AS 1163

7、 Right angle/sharp angle rectangular pipe application

Mechanical guide rail, agricultural machinery framework, steel wood furniture, curtain wall building, large steel structure, mechanical equipment, etc

8、 Sample