Search This Supplers Products:square steel piperectangular steel pipeERW steel pipehot galvanized steel pipelsaw steel pipeseamless steel pipe

-

-

-

ISO9001

Certificate No : 911200005503823816

Issuing authority : ECI

Valid period : 2020/10/30 - 2023/10/29

GB/T19001-2016/ISO9001:2015 standard

In 1979, the Quality Management and Quality Assurance Technology Association (ISO/TC176) was approved and established. It is responsible for formulating international standards related to quality management and quality assurance. In 1987, the world's first series of international standards for quality management and quality assurance - ISO9000 series standards were issued. The birth of this standard is a new era of quality management and quality assurance worldwide, which has played a good role in promoting the quality management of industrial enterprises around the world and the quality assurance of both suppliers and suppliers, as well as promoting international trade exchanges.

Origin and development

Since the early 19th century, with the development of industrial production, how to objectively evaluate the goods has become a concern. The UK is the birthplace of product quality certification in the world. After the British Standards Institute (BSI) published the BS5750 National Standard for Quality Assurance in 1975, BSI held a third-party organization quality system assessment and registration business the next year, which was welcomed by all parties. From the practice of quality system certification, the UK felt that this quality certification model was widely adaptable and flexible, would bring benefits to both producers and customers, and was worth promoting to the international community. Therefore, BSI recommended to the international standardization organization ISO in 1979, hoping that ISO would develop international standards on quality assurance technology and implementation. ISO adopted BSI's recommendations.

significance

Implementing ISO9001 standard and obtaining the third-party quality system certification has become the basic condition for enterprises to win the trust of customers and consumers.

Strengthen management

Eliminate trade barriersIn order to protect their own interests, many countries have set up various trade barriers, including tariff barriers and non-tariff barriers. Among them, non-tariff barriers are mainly technical barriers. Among technical barriers, they are mainly barriers to product quality certification and ISO9000 quality system certification. In particular, in the World Trade Organization, member countries have eliminated tariff barriers from each other and can only set technical barriers. Therefore, obtaining certification is the main way to eliminate trade barriers. After China's entry into the WTO, it has lost the strict distinction between domestic trade and international trade. All trade may encounter the above-mentioned technical barriers, which should be highly valued by the business community and prevented as early as possible.Audit effort and expenseIn modern trade practice, the second party audit has long been a practice, but it has gradually found that it has many disadvantages: an organization usually supplies goods for many customers, and the second party audit will undoubtedly bring a heavy burden to the organization; On the other hand, customers also need to pay a considerable amount of fees, and at the same time consider the experience and level of personnel dispatched or hired. Otherwise, the expected purpose will not be achieved even if the cost is spent. Only ISO9000 certification can eliminate such disadvantages. Because after the first party applied for the ISO9000 certification of a third party and obtained the certification certificate, many second parties do not need to audit the first party. In this way, both the first party and the second party can save much energy or expense. In addition, if an enterprise applies for UL, CE and other product quality certification after obtaining ISO9000 certification, it can also be exempted from the expense of re certification of the enterprise's quality management system by the certification authority.remain invincibleThe means of international trade competition are mainly price competition and quality competition. As the method of low price sales not only reduces profits sharply, but also suffers from trade sanctions if it constitutes dumping, the means of price competition is increasingly undesirable. Since the 1970s, quality competition has become the main means of international trade competition. Many countries have taken improving the quality requirements of imported goods as an important measure of trade protectionism that restricts imports and awards. The implementation of ISO9000 international standardized quality management can steadily improve the product quality, so that enterprises will always be invincible in the product quality competition.Economic cooperation and exchangeIn accordance with the practice of international economic cooperation and technical exchange, both parties must have a common language, a unified understanding and a common standard in terms of product (including service) quality before they can conduct cooperation and exchange. ISO9000 quality management system certification just provides such trust, which is conducive to the rapid agreement between the two parties.

-

-

-

-

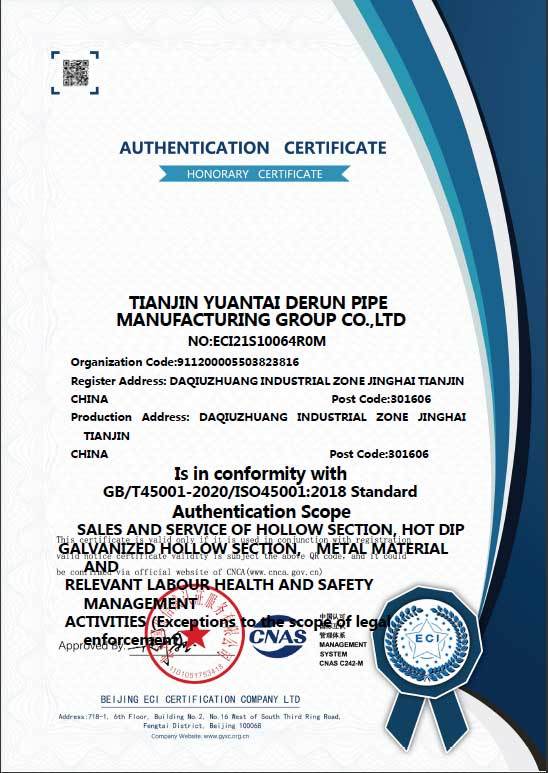

ISO45001

Certificate No : ECI21E00064R0M

Issuing authority : ECI

Valid period : 2021/5/11 - 2024/5/10

The environmental management system conforms toGB/T24001-2016/ISO14001:2015

The full name of ISO14001 certification is ISO14001 environmental management system certification, which refers to the conformity assessment activities carried out by a third-party certification body according to ISO14001 standards. ISO14001 is a standard issued by the International Organization for Standardization and one of the ISO14000 family of standards. This standard was first issued in 1996 and revised by the ISO International Organization for Standardization in 2004. The latest version is ISO14001-2015.

brief introduction

ISO14001 certification is applicable to any organization, including enterprises, institutions and relevant government units. After certification, it can be proved that the organization has reached the international level in environmental management, can ensure that the control of various pollutants in various processes, products and activities of the enterprise meets the relevant requirements, and helps the enterprise establish a good social image.

Target indicatorsThe organization shall establish, implement and maintain documented environmental objectives and indicators for its internal functions and levels.Where feasible, goals and targets should be measurable. The objectives and indicators shall conform to the environmental policy and include the commitment to pollution prevention, continuous improvement and compliance with applicable laws, regulations and other requirements.When establishing and reviewing objectives and indicators, the organization shall consider laws, regulations and other requirements, as well as its own important environmental factors. In addition, optional technical solutions, financial, operational and operational requirements, and views of interested parties should also be considered.The organization shall develop, implement and maintain one or more programs for achieving its goals and targets, which shall include:a) Specify the responsibilities of relevant functions and levels within the organization to achieve goals and targets;b) The method and schedule for achieving goals and targets.

requirementa. The organization shall provide the certification authority with sufficient information on the operation of the environmental management system. For multiple sites, the certification scope, address and personnel distribution of each site shall be described. The certification authority will audit multiple sites by sampling;b. ISO14001 certification consultation is a conformity verification activity to collect objective evidence. To ensure the smooth implementation of the audit, the organization shall make necessary arrangements for the certification body to carry out certification audit, tracking audit, supervision audit, review and certificate replacement, and solve complaints, including document review, on-site audit, access to relevant records and visitors;c. The organization shall establish a documented environmental management system that meets the requirements of ISO14001 standard, complete internal audit and management review before applying for certification, and ensure the effective and full operation of the environmental management system for more than three months;d. In case of any change in the organization's environmental management system or any major change affecting the compliance of the environmental management system, the certification authority shall be notified in a timely manner; The certification authority will conduct supervision audit, certificate renewal audit or review as appropriate to maintain the validity of the certificate;e. After obtaining the certificate, the organization shall comply with the relevant requirements of the certification authority. When conducting publicity, the organization shall only make a statement on the scope of the approved certification, and comply with the provisions of the certification authority on the use of certification certificates and certification marks; During the supervision and audit, the certification authority will audit the use of the certification certificate and logo;f. Since the establishment of the environmental management system, the organization shall maintain the self-assessment of the compliance with laws and regulations, and submit the compliance certificate of the organization for more than one year. Necessary corrective measures shall be taken in time in case of non-compliance with relevant laws and regulations;g. The organization shall provide the certification authority with records of information communication and complaints with interested parties, as well as records of corrective actions taken.

RangeThis standard specifies the requirements for the environmental management system to enable an organization to formulate and implement environmental policies and objectives in accordance with laws and regulations and other requirements it should comply with, as well as information on important environmental factors. It applies to those environmental factors that the organization determines can control or may exert influence. However, the standard itself does not propose specific environmental performance criteria. This standard is applicable to any organization with the following aspirations:a) Establish, implement, maintain and improve the environmental management system;b) Make sure that they can meet the declared environmental policy;c) Demonstrate compliance with this standard by:;1) Conduct self-evaluation and self declaration;2) Seek confirmation of the organization's conformity from interested parties (such as customers);3) Seek external confirmation of its self declaration;4) Seek external organizations to certify/register their environmental management.All requirements specified in this standard can be incorporated into any environmental management. The extent of its application depends on such factors as the organization's environmental policy, its activities, the nature of its products and services, and its operating site and conditions. This standard also provides an informative guide on how to use this standard in Appendix A.

applyThe company shall meet the following conditions when applying for ISO14001 certification:1. Within one year before the application date, he has not been punished by the local environmental protection authority and has obtained the compliance certificate from the environmental protection authority;2. Pollutant discharge shall comply with national or local pollutant discharge standards;3. The products applied for certification belong to the category list of environmental labeling products that can be certified published by the State;4. Comply with the national standards or technical requirements for environmental labeling products;5. Normal batch production and stable technical indicators;6. Establish the guarantee system of environmental labeling products;7. It shall have the product quality certification certificate or product production license certificate, or the product quality certificate within one year issued by the inspection agency recognized by the standardization administrative department above the provincial level;8. Environmental monitoring report within the validity period, including water, sound, gas, etc.

technological processISO14000 certification process:1. Certification consulting2. Certification application3. Sign the contract4. Phase I review5. Phase II review6. Nonconformity correction and tracking verification7. Approval and issuance8. Post certificate supervision

significanceThe ISO 14000 series of standards is, in the final analysis, a set of management standards. It is the crystallization of environmental management experience of industrial developed countries. When formulating national standards, the situation of different countries has been taken into account to make the standards as common as possible.·The positive impact of ISO 14001 standards on enterprises is mainly reflected in the following aspects:·Establish enterprise image and improve enterprise reputation·Promote enterprises to consciously abide by environmental laws and regulations·Promote enterprises to consider their impact on the environment in their production, operation, service and other activities, and reduce the environmental load·Enable enterprises to obtain the "green pass" to enter the international market·Enhance the environmental awareness of enterprise employees·Promote enterprises to save energy, recycle waste and reduce operating costs·Promote enterprises to strengthen environmental management

Main impactsIn 1996, ISO first issued five standards related to environmental management system and its audit, which attracted the attention of governments and industry. By the end of 1997, only one year after the promulgation of the standard, 1491 enterprises in the world had passed the ISO14001 standard certification; By the end of 1998, the number had reached 5017; By the end of 1999, more than 10000 enterprises had passed the certification.Our government attaches great importance to environmental management. The five standards that have been issued have been transformed into national standards. They are:GB/T24001-1996 idt ISO14001 Environmental Management System Specification and Guidance for UseGB/T24004-1996 idt ISO14004 Environmental Management Systems - Guidelines for Principles, Systems and Support TechnologiesGB/T24010-1996 idt ISO14010 General Principles of Environmental Audit SystemGB/T24011-1996 idt ISO14011 Environmental Audit System Audit Procedure Environmental Management System AuditGB/T24012-1996 idt ISO14012 Environmental Audit System Qualification Requirements for Environmental AuditorsAmong them, ISO14001 is the core of this series of standards. It is not only the basis for establishing the environmental management system and auditing or reviewing the environmental management system, but also the basis for formulating other ISO14000 series standards.The important feature of ISO14000 series standards is that, first of all, the standards are not mandatory, but voluntary. The ISO14000 series standards draw on the successful experience of the ISO9000 standard, making the standard widely applicable and flexible. It can be applied to organizations of any type and size under different geographical, cultural and social conditions. The ISO14000 series standards have good compatibility with ISO9000 standards, which enables enterprises to effectively coordinate with the original management system when adopting ISO14000 series standards. "Prevention first" is the leading ideology running through ISO14000 series standards, which requires enterprises to commit to pollution prevention and implement it in the system. Continuous improvement is the soul of ISO14000 series standards. Through the implementation of the standards, the organization has established a mechanism for continuous improvement. In the process of continuous improvement, it realizes its commitment to society and ultimately achieves the goal of improving environmental performance.The implementation of ISO14000 series standards is conducive to improving the environmental awareness of the whole nation and establishing the idea of sustainable development; It is conducive to improving people's awareness of abiding by the law and the implementation of environmental laws and regulations; It is conducive to mobilizing the initiative of enterprises to prevent and control environmental pollution, and promoting enterprises to continuously improve environmental management; It is conducive to promoting the conservation and rational utilization of resources and energy; It is conducive to achieving bilateral and multilateral certification of environmental certification among countries and eliminating technical barriers to trade.

-

-

-

-

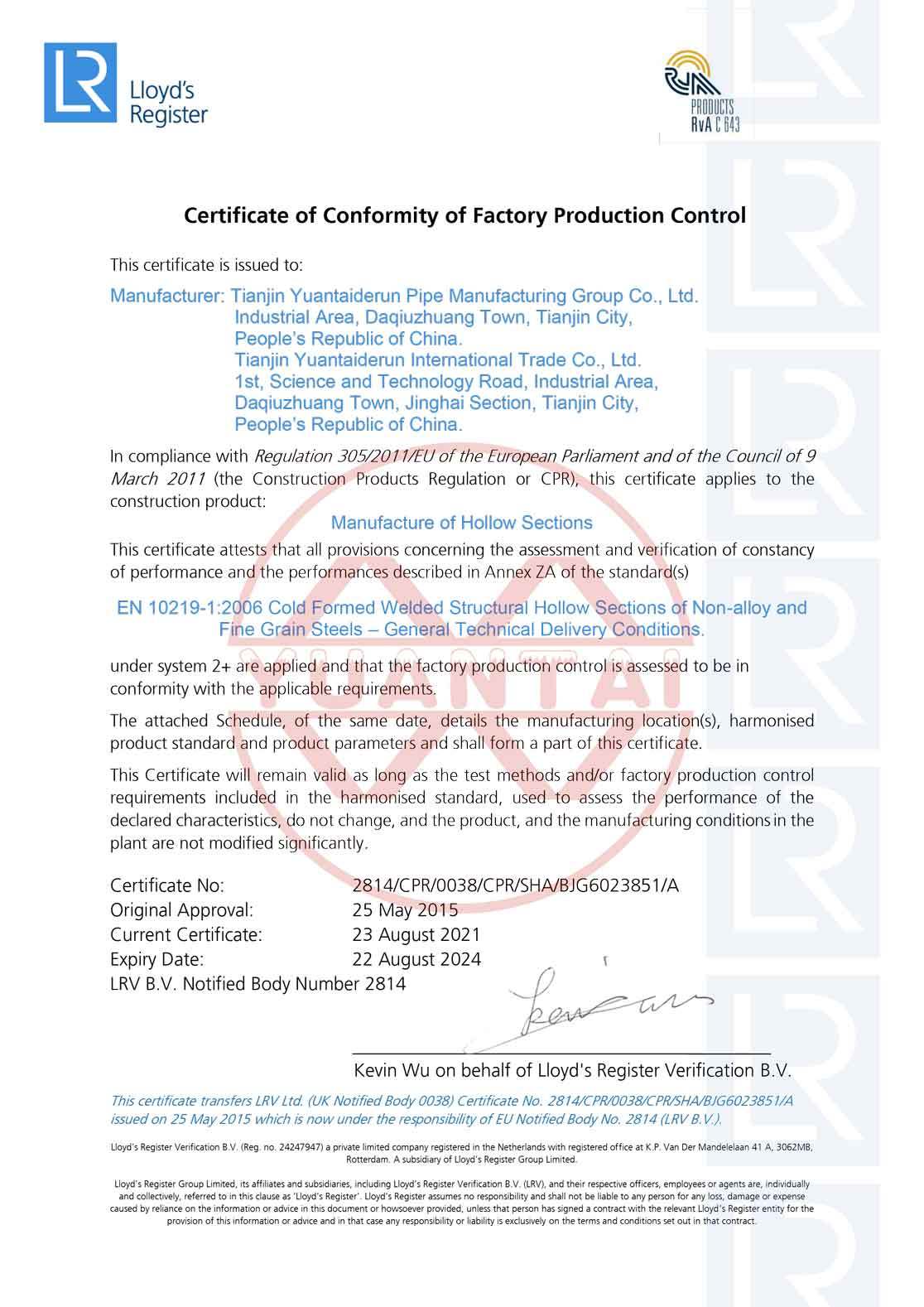

EN10219

Issuing authority : Lloyd's Register Verification B.V.

Valid period : 2021/8/23 - 2024/8/22

EN10219-1:2006 Certificate of Conformity of Factory Production Control

Cold formed weldedstructural hollowsections of non-alloyand fine grain steels —Part 2: Tolerances, dimensions andsectional propertiesThe European Standard EN 10219-2:2006 has the status of aBritish StandardICS 77.140.75BS EN 10219-2:2006This British Standard waspublished under the authorityof the Standards Policy andStrategy Committeeon 31 May 2006© BSI 2006ISBN 0 580 48464 5National forewordThis British Standard is the official English language version ofEN 10219-2:2006. It supersedes BS EN 10219-2:1997 which is withdrawn.The UK participation in its preparation was entrusted to Technical CommitteeISE/12, Structural steel, which has the responsibility to:A list of organizations represented on this committee can be obtained onrequest to its secretary.Cross-referencesThe British Standards which implement international or Europeanpublications referred to in this document may be found in the BSI Catalogueunder the section entitled “International Standards Correspondence Index”, orby using the “Search” facility of the BSI Electronic Catalogue or of BritishStandards Online.This publication does not purport to include all the necessary provisions of acontract. Users are responsible for its correct application.Compliance with a British Standard does not of itself confer immunityfrom legal obligations.— aid enquirers to understand the text;— present to the responsible international/European committee anyenquiries on the interpretation, or proposals for change, and keep UKinterests informed;— monitor related international and European developments andpromulgate them in the UK.Summary of pagesThis document comprises a front cover, an inside front cover, the EN title page,pages 2 to 36, an inside back cover and a back cover.The BSI copyright notice displayed in this document indicates when thedocument was last issued.Amendments issued since publicationAmd. No. Date CommentsEUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10219-2April 2006ICS 77.140.75 Supersedes EN 10219-2:1997English VersionCold formed welded structural hollow sections of non-alloy andfine grain steels - Part 2: Tolerances, dimensions and sectionalpropertiesProfils creux pour la construction soudés, formés à froid enaciers non alliés et à grains fins - Partie 2 : Tolérances,dimensions et caractéristiques de profilKaltgefertigte geschweißte Hohlprofile für den Stahlbau ausunlegierten Baustählen und aus Feinkornbaustählen - Teil2: Grenzabmaße, Maße und statische WerteThis European Standard was approved by CEN on 16 March 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36 B-1050 Brussels© 2006 CEN All rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10219-2:2006: EEN 10219-2:2006 (E)2ContentsForeword ..........................................................................................................................................................31 Scope ...................................................................................................................................................42 Normative references .........................................................................................................................43 Terms and definitions.........................................................................................................................44 Symbols...............................................................................................................................................45 Information to be obtained by the manufacturer..............................................................................56 Tolerances...........................................................................................................................................57 Measurement of size and shape ........................................................................................................87.1 General ................................................................................................................................................87.2 Outside dimensions............................................................................................................................87.3 Thickness ............................................................................................................................................87.4 Out-of-roundness................................................................................................................................97.5 Concavity and convexity ....................................................................................................................97.6 Squareness of sides .........................................................................................................................107.7 External corner profile......................................................................................................................117.8 Twist...................................................................................................................................................117.9 Straightness ......................................................................................................................................128 Dimensions and sectional properties..............................................................................................12Annex A (informative) Additional tolerances for piling tube.....................................................................14A.1 General ..............................................................................................................................................14A.2 Out of roundness tolerance .............................................................................................................14A.3 Accidental eccentricity tolerance ....................................................................................................15A.4 Dimple tolerance ...............................................................................................................................17Annex B (normative) Formulae for the calculation of sectional properties .............................................20B.1 General ..............................................................................................................................................20B.2 Circular hollow sections...................................................................................................................20B.3 Rectangular, or square, hollow sections.........................................................................................21Annex C (normative) Sectional properties for a limited range of standard sizes ....................................24Bibliography...................................................................................................................................................36

-

-

-

-

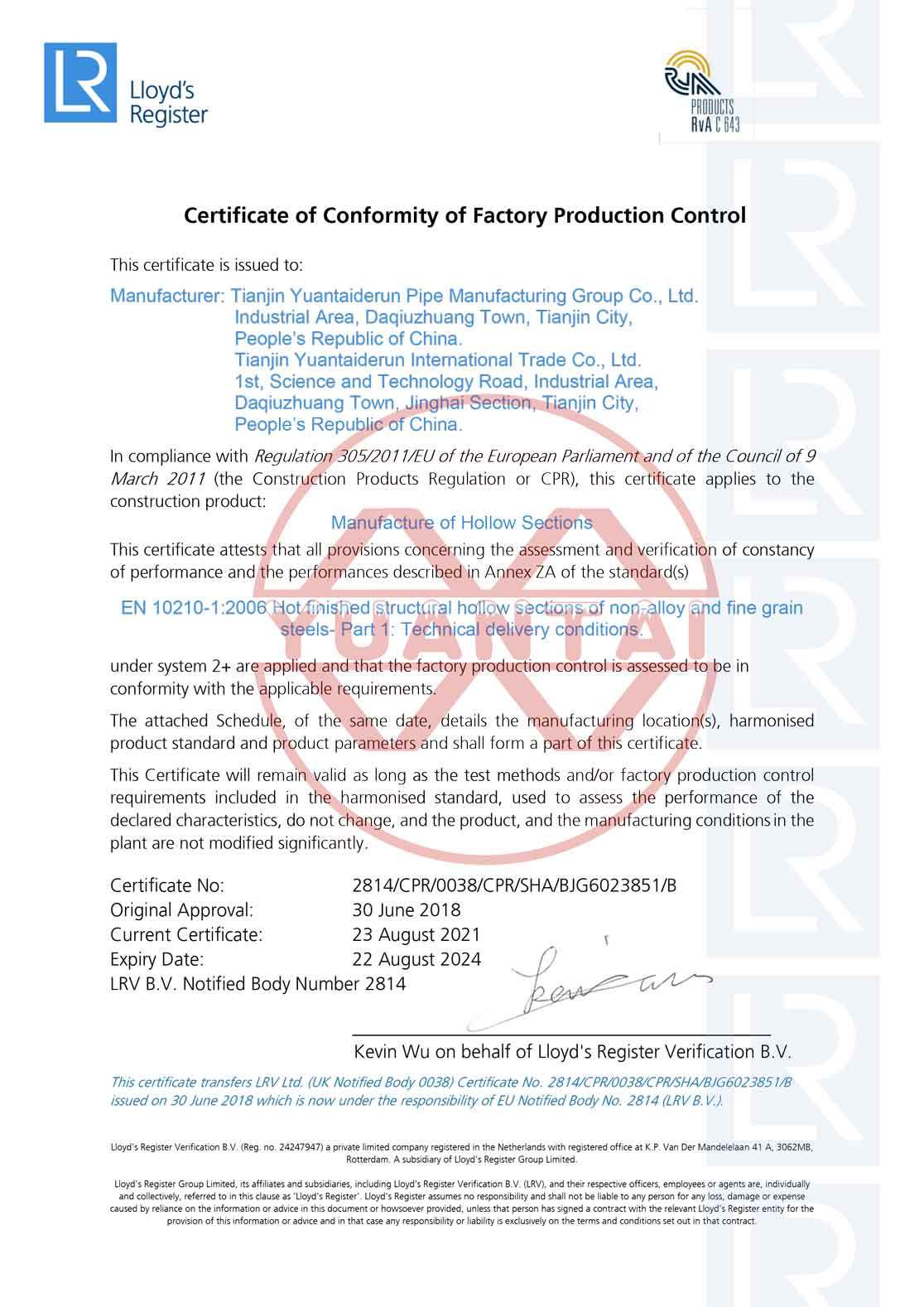

EN10210

Issuing authority : Lloyd's Register Verification B.V.

Valid period : 2021/8/23 - 2024/8/22

Certificate of Conformity of Factory Production Control EN10210-1:2006

This British Standard is the English version of EN10210-2, 1997. It replaces theBS4848 Part II 1991 edition. Britain is entrusted by ISE/12 Structural Steel Technology Association to participate inBe responsible for the preparation of this standard:1. Help users of the standard understand this text.1. The relevant European associations shall resolve the issues related to the interpretation and change of the standards, and inform the British side of the expediency.1. Pay close attention to relevant international and European developments and publish them in the UK.The list of member organizations of the Association can be obtained from the Secretariat.Mutual referenceInternational or European publications cited in this document can be found in the "International Standards Index" in the BSI Standards Catalogue or by using BSISearch engine search of standard electronic catalog.The implementation of British Standards does not enjoy immunity from legal liability.

-

-

-

-

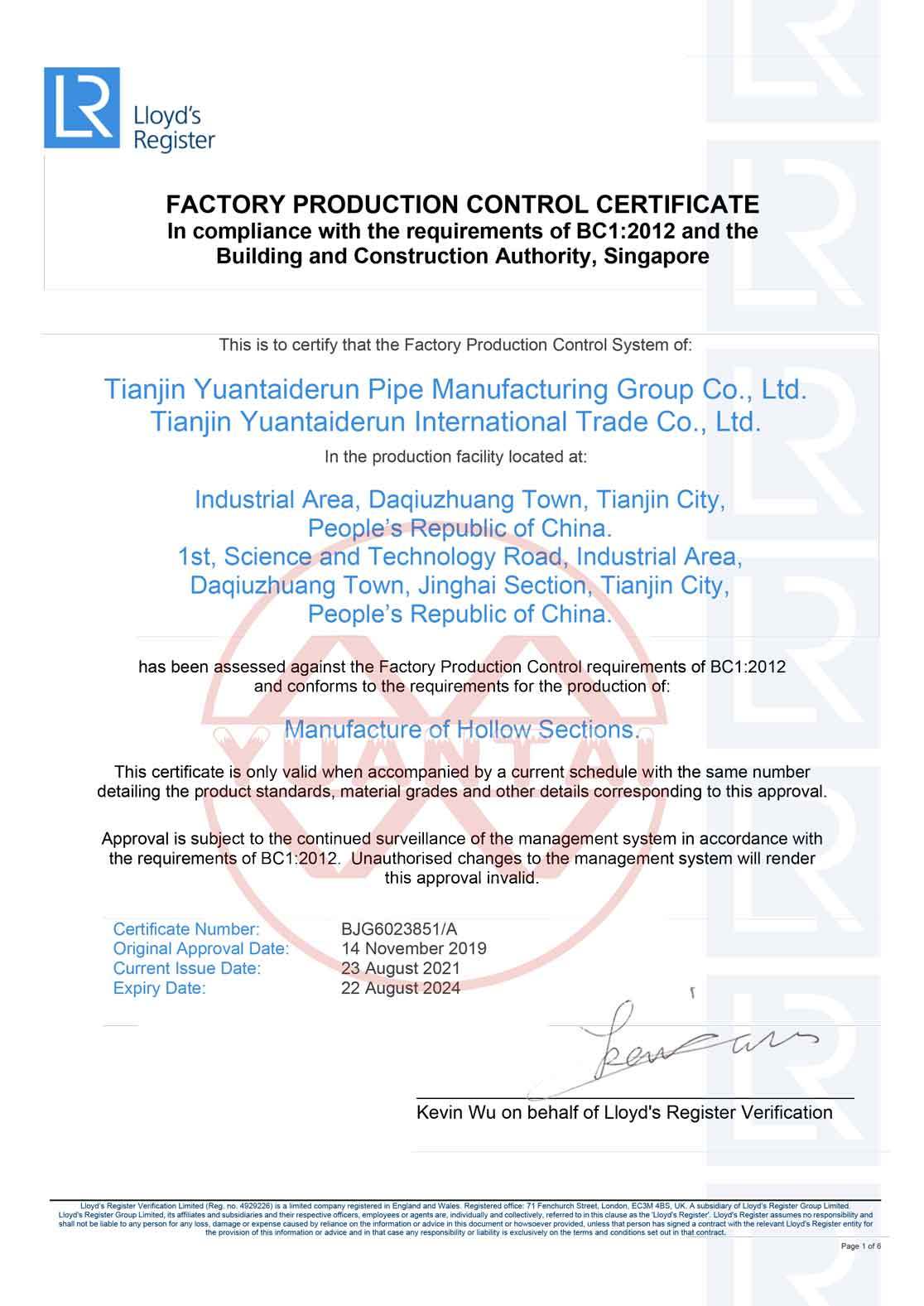

BC1

Issuing authority : Lloyd's Register Verification B.V.

Valid period : 2021/8/23 - 2024/8/22

FACTORY PRODUCTION CONTROL CERTIFICATE IN COMPLIANCE WITH THE REQUIREMENTS OF BC1:2012 AND THE BUILDING AND CONSTRUCTION AUTHORITY,SINGAPORE

Singapore Steel Structure Raw Material System Certification (BC1-FPCC)

The quality control of steel structure raw materials is directly related to the compliance of the whole project quality, especially Singapore's raw material standards and quality requirements for steel structure products are quite strict. We will provide exclusive certification services for the quality system of steel structure manufacturers to help you ensure the quality of steel structures and ensure the smooth progress of the project.

Specific certification content1. Review the quality management system;2. Qualification evaluation of key personnel;3. Review technical documents;4. FPC (raw material site, blanking, material tracing, forming, rolling, heat treatment, surface treatment, assembly, packaging, transportation) inspection at the factory production site;5. Field verification of key processes (such as blanking and forming);6. Sample quality inspection;7. Issue non conformance report;8. Issue the pre audit report;9. Issue FPCC certificate.

-

-

-

-

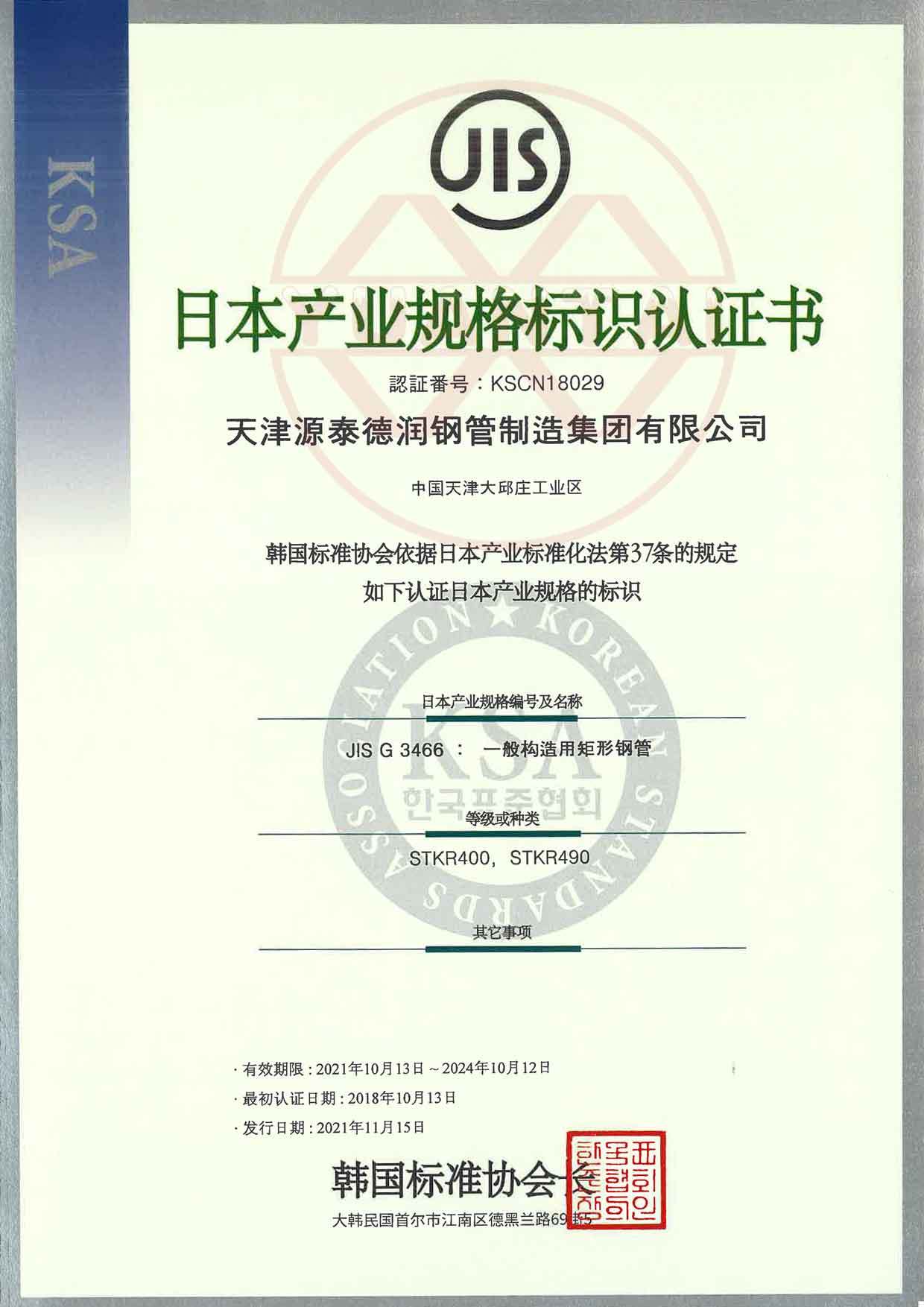

JIS

Certificate No : KSCN18029

Issuing authority : KSA

Valid period : 2021/10/13 - 2024/10/12

JIS G3466 CERTIFICATE

1、 Introduction to JIS Certification

JIS is the abbreviation of Japanese Industrial Standards and the most important and authoritative standard among Japanese national standards. It was formulated and reviewed by the Japanese Industrial Standards Survey (JISC) according to the Japanese Industrial Standardization Law to promote the national standardization of Japanese industry, including the shape, quality, performance, production methods, testing methods, etc. of industrial products.According to the Japanese Industrial Standardization Law, the objects of JIS certification involve various industrial fields, except for drugs, pesticides, chemical fertilizers, silk, food and other agricultural and forestry products that have special standards or technical specifications. As of the end of July 2007, there were 10124 current JIS standards. The product manufacturer must pass the compliance assessment to obtain the certificate of compliance.

2、 JIS certification process

The JIS certification process includes the following five steps:-Certification application-Product testing-Factory review (as appropriate)-Certificate issuance-Stick JIS mark on the productThe certification authority will assign auditors to the factory to review its quality system. In order to maintain the validity of the JIS identification certificate, the subsequent audit shall be conducted every three years, including new product testing and change audit. The normal processing cycle from the application for certification to the issuance of the certificate is generally 6-9 months, and the work cycle will be extended if the requirements are not met.Depending on the type of product certification, factory audits may be required.

3、 Japanese JIS certification mark

Signs are divided into the following three types:① JIS mark for industrial products② JIS mark for processing technology③ JIS mark for specific purpose

4、 Type of products covered by JIS certificationThe JIS logo covers a wide range of products, mainly divided into the following categories:– Civil engineering and construction– Mechanical Engineering– Electronic and electrical engineering– Automotive Engineering– Railway engineering– Shipbuilding– Ferrous materials and metallurgy– Non ferrous materials and metallurgy– Chemical Engineering– Textile Engineering– Mining– Pulp and paper– Management system– Ceramics– Housewares– Medical equipment and safety appliances– Aircraft and aviation– Information processing– Services– Other

-

-

-

-

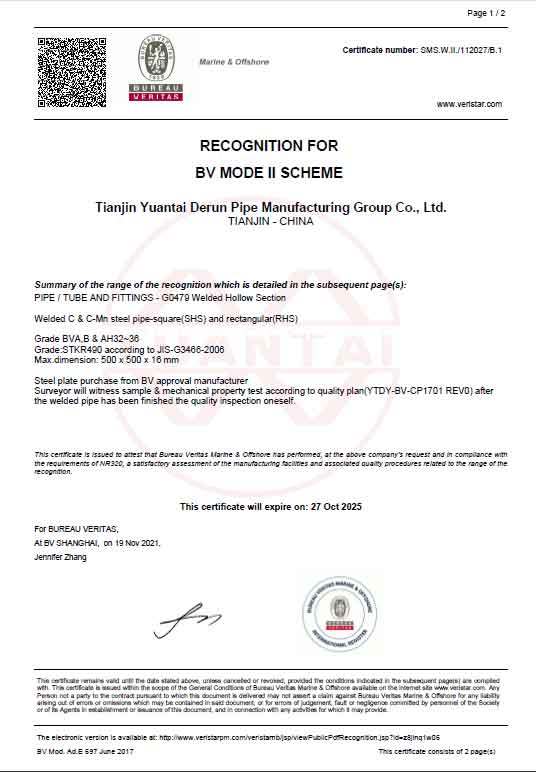

BV certification

Issuing authority : Bureau Veritas

Valid period : 2021/10/28 - 2025/10/27

BV certification

BVQI is an international organization under the Bureau Veritas (also known as Bureau Veritas, or BV for short, founded in 1828), which specializes in quality and environmental system certification and other industry standard certification. Its headquarters are located in London.BVQI is an authoritative certification agency with the largest number of certification companies (the second largest in the world) and outstanding reputation. BVQI participated in the formulation of ISO9000 standards and a series of industry standards, making great contributions to the development and promotion of standards. BVQI is recognized as the world's most international certification body by experts in more than 580 offices in 154 countries. Because of this, BVQI's certification has won the most extensive international recognition.

Extended dataThe headquarters has six departments, which are respectively engaged in ship inspection (BV is also called French Classification Society in this business), import and export commodity inspection, industrial product inspection, container inspection, engineering supervision, system certification, product certification, and aerospace inspection. Its subsidiaries include ACTS (American Test Laboratory), LCIE (French National Electronic and Electrical Laboratory)ATL (Engineering Management Consulting), BIVAC (International Import and Export Commodity Inspection Bureau), CEP Industry (Material Testing, Metallurgy and Environmental Analysis), CEP System (New Technology Risk Assessment), TECNITS (Investment Analysis, Project Management), BIO-CONTRL, Union International&Neptunus (Active Container Inspection), BVC (System Certification).Bureau Veritas is one of the most recognized organizations in the industry by governments and international organizations around the world. Bureau Veritas is a world-renowned international inspection and certification group. Provide professional inspection, analysis, audit, product and facility (building, industrial site, equipment, ship, etc.) certification and relevant mandatory or voluntary management system certification services.Participated in the formulation of ISO9000 and ISO14000 standards and a series of industrial standards, making great contributions to the development and promotion of standards. It ranked first in the American Quality Digest in 2000 and the ISOS survey in Japan in 2002.BVI's mission is to inspect, verify and certify customers' properties, projects, products or management systems through its own industry reference standards or external standards, and finally submit compliance reports or certificates.Bureau Veritas is committed to creating value for customers through risk management and performance optimization. The Group provides a variety of solutions for the needs of small and medium-sized enterprises, large transnational groups or government agencies.Therefore, BVI's services cover many markets, such as shipbuilding and construction engineering, industrial manufacturing, energy and chemical industry, consumer goods, transportation and logistics, and service industry.The main businesses of the Group can be listed as follows: LEED certification consulting service, China green building evaluation mark certification consulting service, verification at different stages of building construction, laboratory testing of raw materials and consumer goods, ship inspection or marine engineering construction planning audit, control of industrial facilities' impact on the environment, product pre shipment inspection, product and management system certification, etc.

-

-

-

-

Business license

Certificate No : 911200005503823816

Issuing authority : State Administration of market supervision

Valid period : 2010/3/3 - 2030/3/2

The business license is the certificate issued by the administrative department for industry and commerce to the industrial and commercial enterprises and individual operators to permit them to engage in certain production and business activities. The format shall be uniformly prescribed by the State Administration for Industry and Commerce.The registered items are: name, address, person in charge, amount of capital, economic composition, scope of business, mode of operation, number of employees, duration of operation, etc. The business license is divided into original and duplicate, both of which have the same legal effect. The original shall be placed in an eye-catching position at the company's domicile or business premises. The business license shall not be forged, altered, leased, lent or transferred.Industrial and commercial enterprises or self-employed operators without business licenses are not allowed to start business, and they are not allowed to engrave official seals, sign contracts, register trademarks or publish advertisements. Banks are not allowed to open accounts.

-

-

-

-

High tech enterprise certificate

Certificate No : GR202112003736

Issuing authority : STB&FTB&TB

Valid period : 2021/10/9 - 2024/10/9

High tech enterprise

(1) Benefits of high-tech enterprise identification1. Promote the development of innovative enterprisesIf an enterprise wants to become bigger and stronger, it cannot do without technological innovation and reform. The recognition of high-tech enterprises is a guiding policy tailored for resident enterprises by the state. If an enterprise wants to achieve sustainable development, it must try to change its structural model, and take the road of high-tech research to have a steady stream of power for the company to go on.2. Create a good image of the companyA company that studies high and new technology, closely follows the national policy, follows the development of the times, walks in the forefront of science and technology, and gives a different image to the outside world. High tech enterprises believe that they can improve the company's image, attract more partners for the company, and increase the number of partners.3. Enjoy national preferential policiesThe State implements a tax reduction policy for high-tech enterprises in terms of tax revenue. The tax rate will be reduced by 10 percent and the tax amount will be reduced by 40 percent. High tech enterprises have been recognized to enjoy a number of national preferential policies and strong support from the state, providing continuous impetus for the development of the company.4. Expand the market for enterprisesResearch on high and new technology and strive for excellence. High and new technology enterprises believe that they can enhance the company's market value, which is an important weapon for enterprises facing peer competition. With the progress of the times, more and more technologies need to be updated. The more advanced and mature the technology mastered, the more likely the person will be successful.5. Increase capital value for enterprisesThe progress of the times cannot be separated from high-tech, and the development of the country cannot be separated from the active innovation of enterprises. The recognition of high-tech enterprises that can attract more amplitude support for enterprises is an important condition for enterprises to attract investment from other companies. It is also more attractive to the venture capital industry and foreign finance, and can quickly occupy the capital market.6. Attract more talents for enterprisesThe establishment of more research groups is conducive to talent introduction. High and new technology enterprises can obtain more government support, enjoy more national preferential policies, and lay a solid foundation for talent introduction. Students learn more theoretical knowledge from school, while enterprises can provide more practical opportunities, which is a highlight of attracting talents.7. Improve product awarenessA product that closely follows the development of the times is in line with social needs. It is also the product of high-tech research. High and new technology enterprises can promote the popularity of the company's products and make the products more perfect.Identification field of high-tech enterprises1. Electronic information technology: software technology, microelectronics technology, computer and network technology, communication technology, radio and television technology, information security technology, intelligent transportation technology, etc.2. Biology and new medical technology: traditional Chinese medicine, natural medicine, chemical medicine, new dosage forms and preparation technology, medical equipment and software, light industry and chemical biotechnology, and modern agricultural technology.3. Aerospace technology: air control system, civil aviation operation support system, satellite communication application system, navigation application service system, etc.4. New material technology: metal materials, inorganic non-metallic materials, polymer materials, biomedical materials, fine chemicals, etc.5. High tech service industry: modern logistics, integrated circuit, business process outsourcing, cultural and creative industry support technology, public services, technical consulting services, industrial design, etc.6. New energy and energy-saving technology: renewable energy technology, nuclear hydrogen energy, efficient energy-saving technology, etc.7. Resources and environmental technology: water pollution and air pollution control technology, solid waste treatment and comprehensive utilization technology, environmental monitoring technology, circular economy technology, etc.8. Advanced manufacturing and automation: intelligent instruments, advanced manufacturing technology, new machinery, information and automation technology, etc.

-

-

-

-

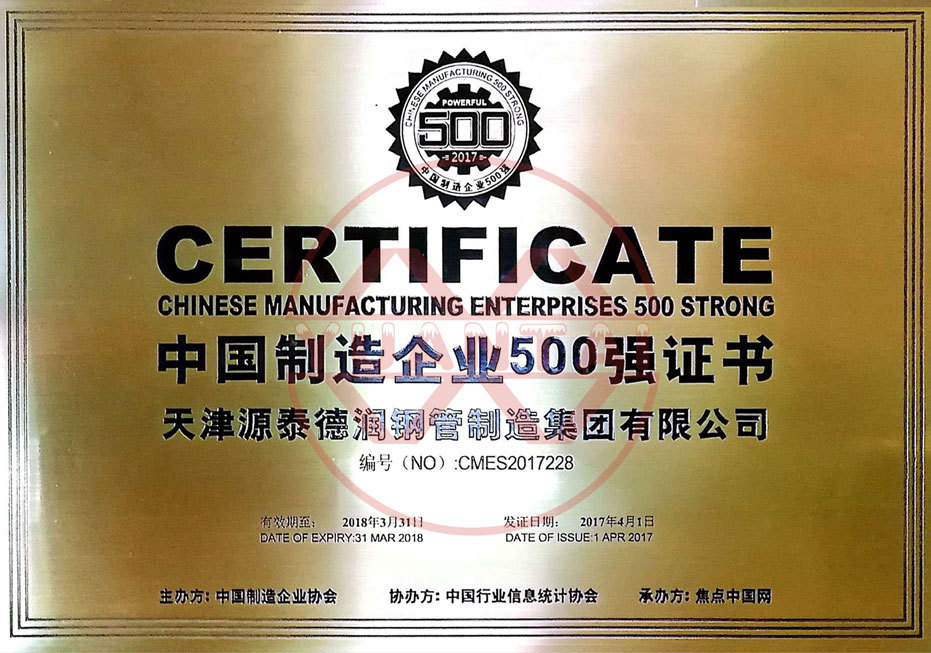

top 500 manufacturer

Certificate No : CMES2017228

Issuing authority : China Manufacturing Enterprise Association

Valid period : 2017/4/1 - 2022/2/14

top 500 manufacturer in China

The top 500 manufacturing enterprises in China show the following characteristics:1. The total amount of operating revenue, growth rate and qualification threshold have been significantly improved2. The growth and fluctuation of asset scale slowed down, and the situation of assets and liabilities improved3. Significant improvement in corporate profitability4. The number of mergers and acquisitions decreased significantly5. The growth of R&D investment was accelerated, and the quantity and quality of patents were improved simultaneously6. Heavy chemical industry still plays an important role in total operating income and total profit contribution

According to the list of China's top 500 manufacturing enterprises, the heavy chemical industry still plays an important role. Except Huawei Investment Holding Co., Ltd., the top 10 enterprises in the list are all heavy chemical enterprises; Ferrometallurgical enterprises accounted for 76 seats in the list of top 500 manufacturing enterprises. The top two industries that contributed the most to the operating revenue were ferrous metallurgy and automobile and spare parts manufacturing, which respectively contributed 14.42% and 13.56% of the overall operating revenue of the top 500 manufacturing enterprises; However, the two industries still contribute the most to the profits, but their positions are interchangeable. 31 automobile and parts manufacturing enterprises have created 14.70% of the total profits of the enterprises on the list, while 76 ferrous metallurgy enterprises have created 14.14% of the total profits of the enterprises on the list.

-

-

-

-

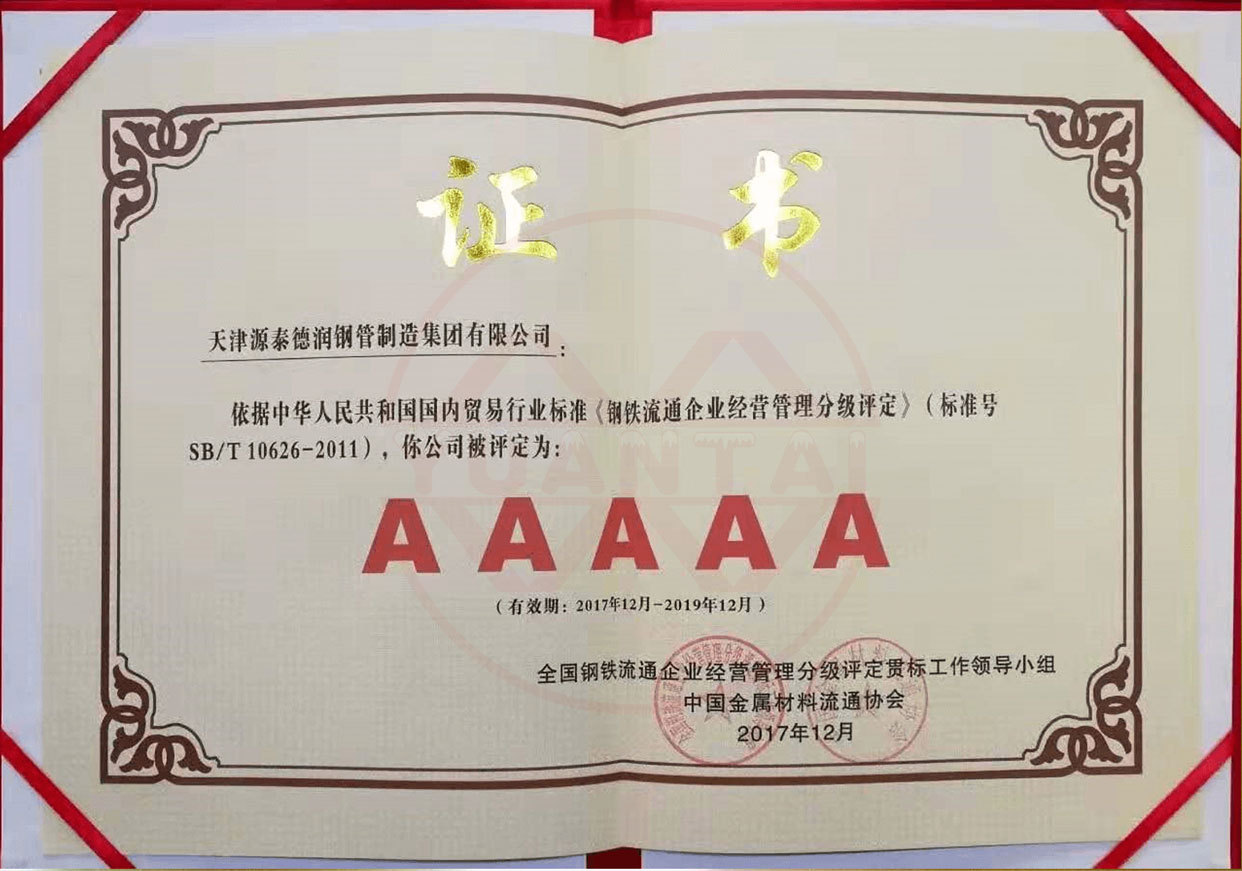

Top 5A enterprises in operation and management of China's iron and steel circulation enterprises

Issuing authority : China Metal Materials Circulation Association

Valid period : 2017/12/14 - 2019/12/14

Top 5A enterprises in operation and management of China's iron and steel circulation enterprises

1. The authoritative credit certificate certification of the enterprise adopts the national standard and is audited and certified by a professional certification authority. The enterprise conforms to the national standard, passes the certification, and issues the certification certificate. The certificate can be found on the CNCA website, which is authoritative and credible. There are too many fake certificates for integrity certification in the market, so we need to identify them carefully!!!2. Enterprises that display and publicize the integrity image can display the certification qualification in the external packaging of the company's products, product manuals, enterprise brochures, enterprise promotional videos, enterprise official websites, media advertisements, personal business cards and other publicity carriers, which is conducive to improving the market image and easier to get the recognition and trust of the market and customers.3. Prevention of enterprise credit risk helps enterprises to establish an effective integrity management system, identify, warn, prevent, control and dispose of possible dishonesty risks, integrity crises and dishonesty behaviors, stipulate relevant processes, and keep them under control, so as to help enterprises continuously improve their integrity level.4. The certification results in a wide range of application fields can be used in government procurement, bidding, investment promotion, business cooperation and other activities to show the authoritative certification of the enterprise's bid reputation, core competitiveness and comprehensive strength.

-

-

-

-

DNV Ship Building Steel Pipe Certification

Certificate No : AMMM00002ZZ

Issuing authority : Dalian NB&CMC

Valid period : 2022/9/29 - 2025/9/28

Historical broadcastDet Norske Veritas Management Services Group was established in 1864. [1]DNV ITGS, a global leader in process improvement, is a combination of four leading consulting companies in various fields in Europe.Globally, DNV ITGS has more than 200 process improvement experts, more than 20 SEI authorized chief assessors and lecturers, implemented more than 100 official evaluations and 300 unofficial evaluations, and has more than 100 leading customers in various industries, ranking first in the European CMMI service field.In China, DNV came to China in 1888 and has nearly 40 offices and more than 600 employees in China. DNV ITGS Asia officially launched consulting services related to process improvement in 2006.Service broadcastUnder the purpose of "protecting life, property and environment", DNV provides customers with comprehensive risk management and various assessment and certification services, mainly involving classification services, certification services, technical services, etc. DNV has set up 300 branches in 100 countries around the world, with about 16500 employees. DNV is based on scientific and technological knowledge and experience. Its main purpose is to protect life and property, and also to protect the natural environment. DNV does its best to manage risks for customers. Offices around the world create a flexible and efficient service network for the organization. Offices have been set up in Chinese Mainland, Hong Kong and Taiwan, China, China. There are 285 employees in Greater China, including professional surveyors, engineers and auditors, who provide various services for different industries, including ship classification and certification, product and management system verification, and scientific and technological services.Advantage broadcastDNV's certification business always adheres to the advantage of leading technology, and has obtained credit recognition from more than 80 countries in the world. It has issued 65000 management system certificates worldwide. As the first international certification authority to enter the Greater China region, DNV Det Norske Veritas has so far established 13 offices in the Greater China region and issued nearly 5000 certificates.Consolidated broadcastDNV and GL announced their official merger. The contract was signed on December 20, 2012, and the new company was renamed DNV GL Group.According to the shipping website, DNV holds 63.5% shares and GL holds 36.5% shares after the merger. The new DNV-GL Group headquarters will be located in Oslo, Norway, but the ship classification service headquarters will be located in Hamburg, Germany. DNV and GL will continue to operate independently, which will guide a new round of development in the maritime industry.According to the calculation of deadweight tonnage of classified ships, DNV and GL Noble Denton are 216 million DWT and 137 million DWT respectively, ranking fourth and fifth respectively in the total tonnage of ships registered by classification societies. After the merger, the total deadweight tonnage of the ships classified by both parties will reach 354 million DWT, which will exceed the total registered tonnage of Japan Classification Society (NK) (321 million DWT) and become the first classification society in terms of registered deadweight tonnage. The total number of registered ships will exceed 12000, which is more than the total number of registered ships of French Classification Society (11000).The combination of DNV and GL not only strengthens its economic strength, but also strengthens its influence. DNV said that since the Nobel Peace Prize event in 2010, its business with China has been affected to some extent. According to the Norwegian Evening Post, Norway's exports to Asia increased last year, but its exports to China decreased by 9% (excluding oil and gas), from 15.3 billion kronor in 2011 to 13.9 billion kronor. If we take into account the exchange rate change between the krona and the RMB, Norway's exports to China fell by 15% last year. The Norwegian Sea Products Committee said that Norwegian salmon used to occupy 90% of the Chinese market, but now it has dropped to 50%. Under such circumstances, DNV's strategic choice is to improve its strength and occupy the market, especially the Chinese market, with the help of GL, which has made a good statement, and its original position and strength.

-

-

-

-

ABS Certificate

Certificate No : PML-T2316300

Issuing authority : ABS Shanghai

Valid period : 2023/1/2 - 2028/1/1

ABS certification of Tianjin Yuantai Derun Steel Pipe Manufacturing Group

As a Gentech person, I understand the importance of selecting the right shipbuilding steel for our customers to ensure the durability and longevity of their vessels. Important shipbuilding steel grades include LR AH36 and ASTM EH36, which have high impact strength and good weldability. Tianjin Yuantai Derun Steel Pipe Manufacturing Group's steel pipe products meet the certification standards of the ABS classification society, and we can provide high-quality steel pipe supplies to shipbuilding steel pipe users worldwide.The quality and price of shipbuilding steel pipes are the key factors to consider before purchasing. The price of shipbuilding steel pipe can also fluctuate depending on market conditions, so it is vital to monitor the market and make an informed purchase. Yuantai Derun's steel pipes are very competitively priced.When selecting the right shipbuilding steel pipe, factors such as the intended use of the vessel, the sailing environment and the loads to be carried must be considered. For example, the ASTM EH36 steel plate is well suited for use in harsh marine environments and has good resistance to seawater corrosion. If you are not sure about this, please contact our account managers and they will answer your questions as soon as possible.In short, shipbuilding steel tubes are an important part of ship construction in the marine industry. The right choice of shipbuilding plate and grade can ensure the durability of the ship and provide a long service life. It is important to understand shipbuilding steel prices, AH36 steel prices and other factors that may influence the purchase decision. Overall, be sure to choose a reputable supplier and source that offers reliable shipbuilding steel grades. Yuantai Delun is a trusted supplier.

-

-

-

-

CNAS

Issuing authority : CNCA

Valid period : 2023/5/18 - 2025/5/17

CNAS CERTIFICATE

In May 2023, Tianjin Bosi Testing Co., Ltd., a subsidiary of Tianjin Yuantai Derun Steel Pipe Manufacturing Group Co., Ltd., passed CNAS certification. Yuantai Derun Group's steel pipe products can be equipped with nationally recognized authoritative third-party inspection reports at the factory.

What is CNAS laboratory accreditation?

CNAS laboratory accreditation is the National Accreditation Commission for Conformity Assessment in China.The China National Accreditation Service for Conformity Assessment (CNAS) is a national accreditation institution established and authorized by the National Certification and Accreditation Administration Commission in accordance with the provisions of the Certification and Accreditation Regulations of the People's Republic of China. It is responsible for the recognition of certification bodies, laboratories, and inspection institutions.CNAS was formed by the merger of the former Chinese certification body, the National Accreditation Service (CNAB), and the former China National Accreditation Service for Laboratories (CNAL). CNAS evaluates and supervises the management and activities of conformity assessment agencies (such as certification agencies, laboratories, inspection agencies), confirms their ability to carry out corresponding conformity assessment activities (such as certification, testing and calibration, inspection, etc.), confirms the authority of their conformity assessment activities, and plays a recognized and binding role.

-

-

-

-

Yuantai Derun Steel Pipe Manufacturing Group - National Square Rectangular Steel Pipe Manufacturing Single Champion Certificate

Issuing authority : MIIT

Valid period : 2022/11/7 - 2023/11/7

Yuantai Derun Steel Pipe Manufacturing Group - National Square Rectangular Steel Pipe Manufacturing Single Champion Certificate

-

-

-

-

API Spec. 5L Certificate

Issuing authority : American Petroleum Institute

Valid period : 2023/7/17 - 2026/7/17

API Spec. 5L Certificate

The release of API 5L standard is a milestone, which has been focused on by pipeline engineers and industry experts around the world. The API 5L standard was developed by the API Technical Committee, mainly covering pipeline manufacturing, installation, inspection, testing, etc. Its main purpose is to make the quality of pipeline steel more stable, longer service life, while ensuring pipeline safety and reliability.

The application for API 5L certification of steel pipe products was submitted by Yuantai Derun in May 2023. 17th July 2023 was passed, and the certification period is until the end of July 2026.In fact, the quality of Yuantai's round pipe has long reached the standard of API 5L certification.

-

-

-

-

Tangshan ISO14001

Certificate No : 23524EZ0050ROM

Issuing authority : Hangzhou Zhongao Quality Certification Co., Ltd.

Institution URL : https://www.cx.cnca.cn

Valid period : 2024/3/29 - 2027/3/28

Compliant with management system standardsGB/T 24001-2016/IS0 14001:2015Certification scope: Steel rolling processing; Manufacturing and sales of cold-rolled steel strips, high-frequency welded pipes, and hot-dip galvanized pipes; Environmental management activities involved in the sale of hot-rolled strip steel (excluding mandatory regulatory requirements)Book number: 23524EZ0050ROM certificateFirst certification date: March 29, 2024Unified Social Credit Code: 91130223347923971TThis certificate was issued on March 29, 2024Registration expiration: March 28, 2027

-

-

-

-

Tangshan ISO45001

Certificate No : 23524SZ0045ROM

Issuing authority : Hangzhou Zhongao Quality Certification Co., Ltd.

Institution URL : https://www.cx.cnca.cn

Valid period : 2024/3/29 - 2027/3/28

Compliant with management system standardsGB/T 45001-2020/IS0 45001:2018Certification scope: Steel rolling processing; Manufacturing and sales of cold-rolled steel strips, high-frequency welded pipes, and hot-dip galvanized pipes; The occupational health and safety management activities involved in the sales of hot-rolled strip steel (excluding mandatory regulatory requirements);Certificate Number: 23524SZ0045R0MFirst certification date: March 29, 2024Unified Social Credit Code: 91130223347923971TThis certificate was issued on March 29, 2024Registration expiration: March 28, 2027

-

-

-

-

Tangshan ISO9001

Certificate No : 23524QZ0057ROM

Issuing authority : Hangzhou Zhongao Quality Certification Co., Ltd.

Institution URL : https://www.cx.cnca.cn

Valid period : 2024/3/29 - 2027/3/28

Compliant with management system standardsGB/T 19001-2016/IS0 9001:2015Certification scope: Steel rolling processing; Manufacturing and sales of cold-rolled steel strips, high-frequency welded pipes, and hot-dip galvanized pipes; Sales of hot-rolled strip steel (excluding mandatory regulatory requirements)Certificate Number: 23524QZ0057ROMFirst certification date: March 29, 2024Unified Social Credit Code: 91130223347923971TThis certificate was issued on March 29, 2024Registration expiration: March 28, 2027

-